Curtis Taylor

Engineering Director

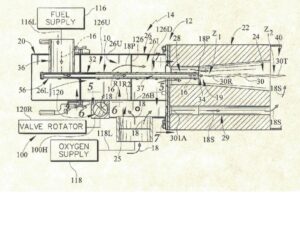

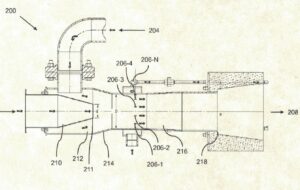

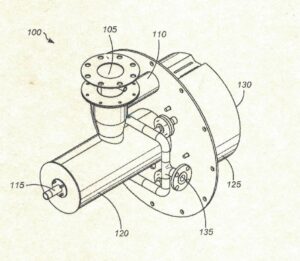

"Over the past 12 years, Marek has been the sole computational fluid dynamics (CFD) resource for the global Honeywell industrial combustion R&D team. During that time, Marek was our "go-to" CFD expert on first-of-a-kind industrial burner concepts and inventions. Marek was also requested by our application engineering teams, to help solve field related combustion, noise, process instability or emissions issues. These issues had usually proven to be beyond the abilities of our field people to solve with typical on-site adjustments or modifications. Providing critical CFD simulation results to help understand and resolve the issues, Marek worked directly with customer engineers, service technicians and local sales leaders to resolve these issues, usually under considerable time pressure.

On all assignments, Marek provided exceptional modeling skill, curiosity, solution generation and a good, positive attitude. He helped drive the development of multiple new burner designs. For these contributions, he was included on multiple US and international patents granted to the combustion team.